-40%

Metron EcoSys Marathon 8500 Gas Scrubber/Burn-Wet Abatement Treatment System

$ 4487.99

- Description

- Size Guide

Description

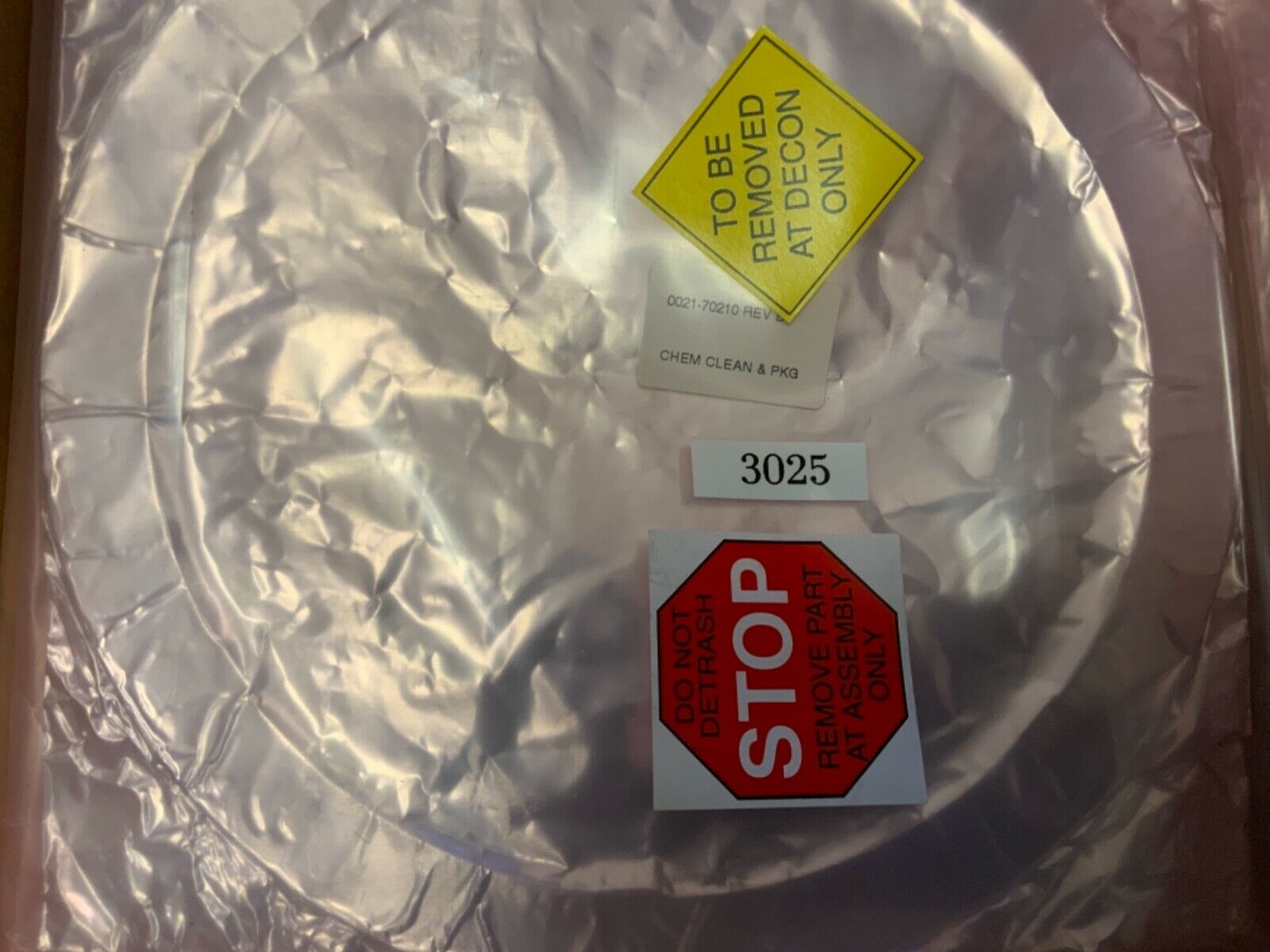

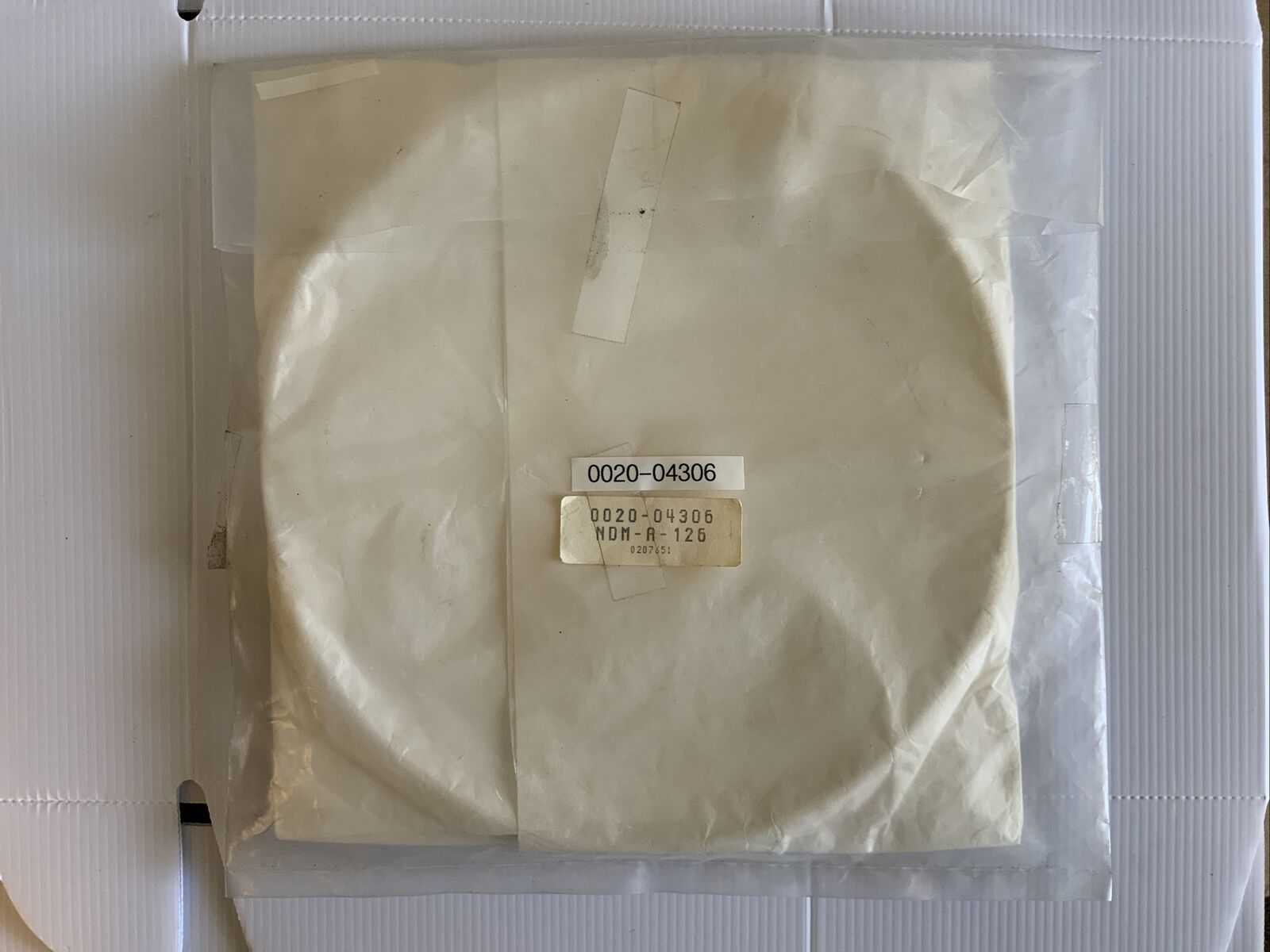

Metron EcoSys Marathon 8500 Gas Scrubber/Burn-Wet Abatement Treatment SystemComes with what you see in the pictures. If you don't see it, you probably won't get it.

Specifications are from EcoSys/Metron and may vary slightly due to upgrades, options, or revisions this unit may or may not have.

This unit is in good condition but we do not have the expertise to fully test it.

The Unit's Serial Number Tag Reads:

Model Number:

Marathon 8500

Part Number:

M5212234131

Schematic Number:

080-17314-00

Serial Number:

MPS-0290

Power Requirements:

208/230 VAC, Single Phase, 50/60 Hz, 13 F.L. Amps

Main CB/Fuse:

230 VAC, 20 A, 10K AIC

Largest Motor/Load Rating:

7 A

Applications:

Semiconductor and flat panel display processes

Advantages:

Excellent PFC's abatement efficiency

Limited NOx and CO emission

Superior particulate management technology

High flow capacity

Reduced water consumption and recirculating water system

Stable thermal processing

Low cost of ownership

Ease of installation and services

Third party certified, SEMI S2 compliance, CE Marked

Ethernet ready

Description:

The Marathon 8500 is an advanced, point-of-use, integrated burn-wet treatment system designed to provide a controlled gas conditioning environment for today’s demanding semiconductor and flat panel display process chemistries. The system is specifically designed for excellent PFCs abatement efficiency to help industries meet their environmental goals and commitments. With its advanced reactor chamber design and smart abatement technology, the Marathon provides superior particulate management for extended PM cycles and a cost-effective abatement solution. The high flow capacity of the Marathon can be configurated to further reduce CoO by handling multiple process tools per abatement unit and provide 100% process tool uptime with automatic backup capability.

Typical Usage Specifications:

Process Flow:

1-4 inlets

Per Inlet:

175 lpm (6 cfm)

Per System:

700 lpm (25 cfm)

Fresh Water Consumption

1

:

0.5 gpm (1.9 lpm)

Clean Dry Air Consumption:

1000 lpm (35.3 cfm)

Chilled Water Consumption

1

:

8 gpm (30 lpm)

Nitrogen Consumption

1

:

15 lpm (0.5 cfm)

Methane Consumption

1

:

40 lpm (1.4 cfm)

Process Exhaust - Static Pressure:

-5" to -2.5" w.c.

Electrical Consumption:

1900 watts

Notes:

1:

Process dependent

Facilities Specifications:

Process Connections:

1-4 inlets, KF40

Nitrogen Gas Source:

70-90 psi (482-620 KPa), 1/2" compression fitting

Clean Dry Air Source:

80-100 psi (552-690 KPa), 3/4" compression fitting

Methane Source:

0.2 - 5 psi (1.4-34.5 KPa), 1/2" Female NPT

Fresh Water Source:

40-60 psi (276-414 KPa), 1/2" Female NPT

Chilled Water Inlet:

55-75 psi (379-517 KPa), 50°F (10°C)

Chilled Water Inlet/Outlet:

1" Female NPT

Sump Pump Drain:

1/2" Female NPT

Process Exhaust:

6" (152 mm) SS or FRP

Electrical Supply:

208/230 VAC, 50/60 Hz, 20 A, 3 Wires

Overall Dimensions:

46" W x 28" D x 90" H (1168 mm x 711 mm x 2286 mm)

Clerance:

36" (914 mm) Front side only

Weight:

1532 lb (695 kg)

0.00 minimum for packaging, handling, and order processing. Shipping to be determined by destination.

Prior to shipment I will need to know the following information (filled out on a form that I will send you) for International Customers or Packages/Freight being Forwarded internationally. International customers may also be subject to a freight forwarder form if applicable.:

(1) Are you the end-user of this item?

(2) If you are not the ultimate end-user of the item, please state the ultimate end user's name.

(3) What is the ultimate country destination?

09/06/19