-40%

Lam Research AutoEtch 590B/590 Dry Oxide Plasma Etch Etcher

$ 6599.99

- Description

- Size Guide

Description

Lam Research AutoEtch 590B Dry Oxide Plasma Etch EtcherComes with what you see in the pictures. If you don't see it, you probably won't get it.

Specifications are from Lam and may vary slightly due to upgrades, options, or revisions this unit may or may not have.

This unit came from a local university. We do not have the facilities or expertise to test it. It is being sold as-is, for parts or not working as such.

The Unit's Serial Number Tag Reads:

Model Number:

590B

Serial Number:

1863

Power Requirements:

208 VAC

Description:

The AutoEtch 590 reduces ion bombardment and attendant device damage by placing the wafer on the grounded electrode. Narrow electrode spacing and high power densities create an intense, focused plasma that promotes high oxide etch rates with low DC-biases.

The 590 is widely used in contact, via, pad, and planarization etches where programmable etching parameters allow precise control of resist erosion for sloped intermetal via etching, or high selectivity to poly and doped silicone, as in shallow CMOS contact etches.

High sensitivity of the optical endpoint detection system permits accurate endpointing on as little as 2 percent exposed area. A specially designed graphite electrode assures process purity. Engineered for long life, the electrode is quickly replaced when change is required.

AutoEtch 590 Exclusive Features:

Fully automated microprocessor operation.

Safe, high-throughput vacuum loadlocked operation.

Programmable, variable electrode spacing.

Convenient Recipe Programming Modules.

Easy-to-read CRT monitoring.

Sensitivity, reliable endpoint detection.

Simple, compact design.

High-uptime, quick-change cathode.

Specifications:

System:

Microprocessor-based, single-wafer, vacuum loadlocked, cassette-to-cassette plasma etching system.

Applications:

Via, contact, planarization, and pad etching on silicon and GaAs substrates.

Wafer Handling:

Wafer Sizes:

3", 100-, 125-, and 150- mm.

Cassettes:

Accepts all standard 25 wafer cassettes.

Loadlocks:

Include backside wafer handling system that transports wafers without exposing moving parts to plasma. Isolate process chamber from ambient contaminants. Employ soft vent/soft pump to minimize turbulence.

Operation:

Processing is automatic when cassettes are loaded. Programmed etch sequences are stored in solid state Recipe Programming Modules. CRT displays wafer locations, process variables, and etch status. Entire system is under closed-loop feedback control. Keylocked to prevent unauthorized process alteration.

Process Variables:

Pressure, RF power, gas flows, electrode spacing, and step termination individually programmable up to 15 process steps. Settable upper and lower electrode temperature.

CRT Display Modes:

Processing:

System Status page.

Process Development:

Recipe, System Parameters, Endpoint Parameters pages.

Maintenance:

"Micro" and "Macro" direct machine control pages.

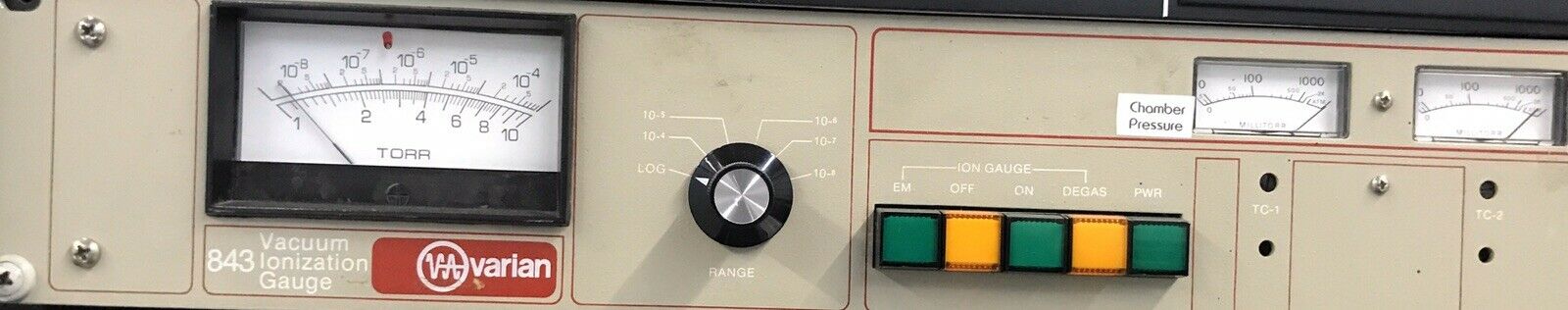

Endpoint Detection:

Optical emission system. Two endpoint detectors standard (405/520 nm); up to four can be used

Step Terminations:

Time/endpoint, percent overetch, stability/time, and recipe.

Process Chamber:

Configuration:

11.5" diameter, anodized aluminum. Machined from solid stock to eliminate welds and ensure vacuum integrity.

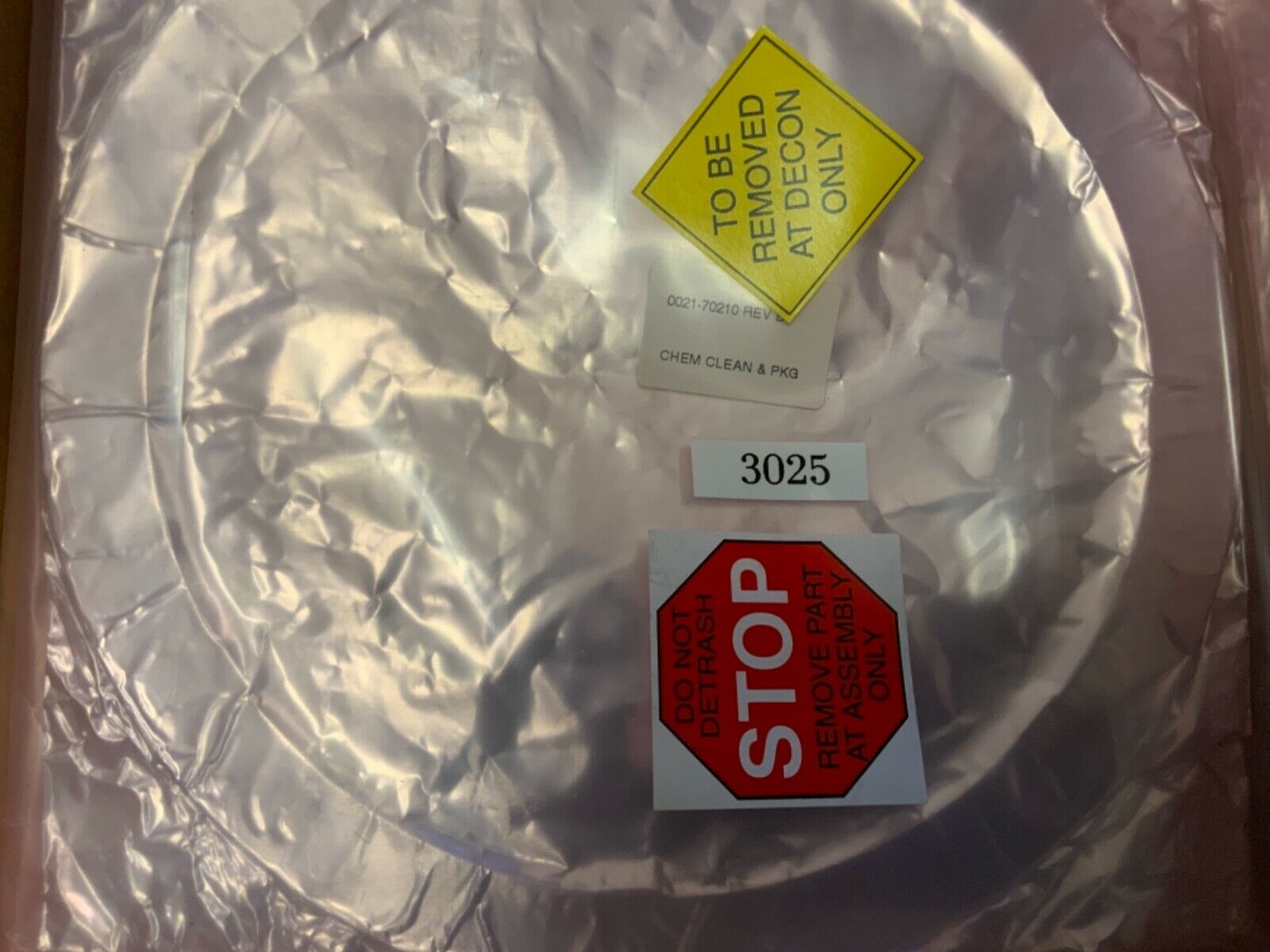

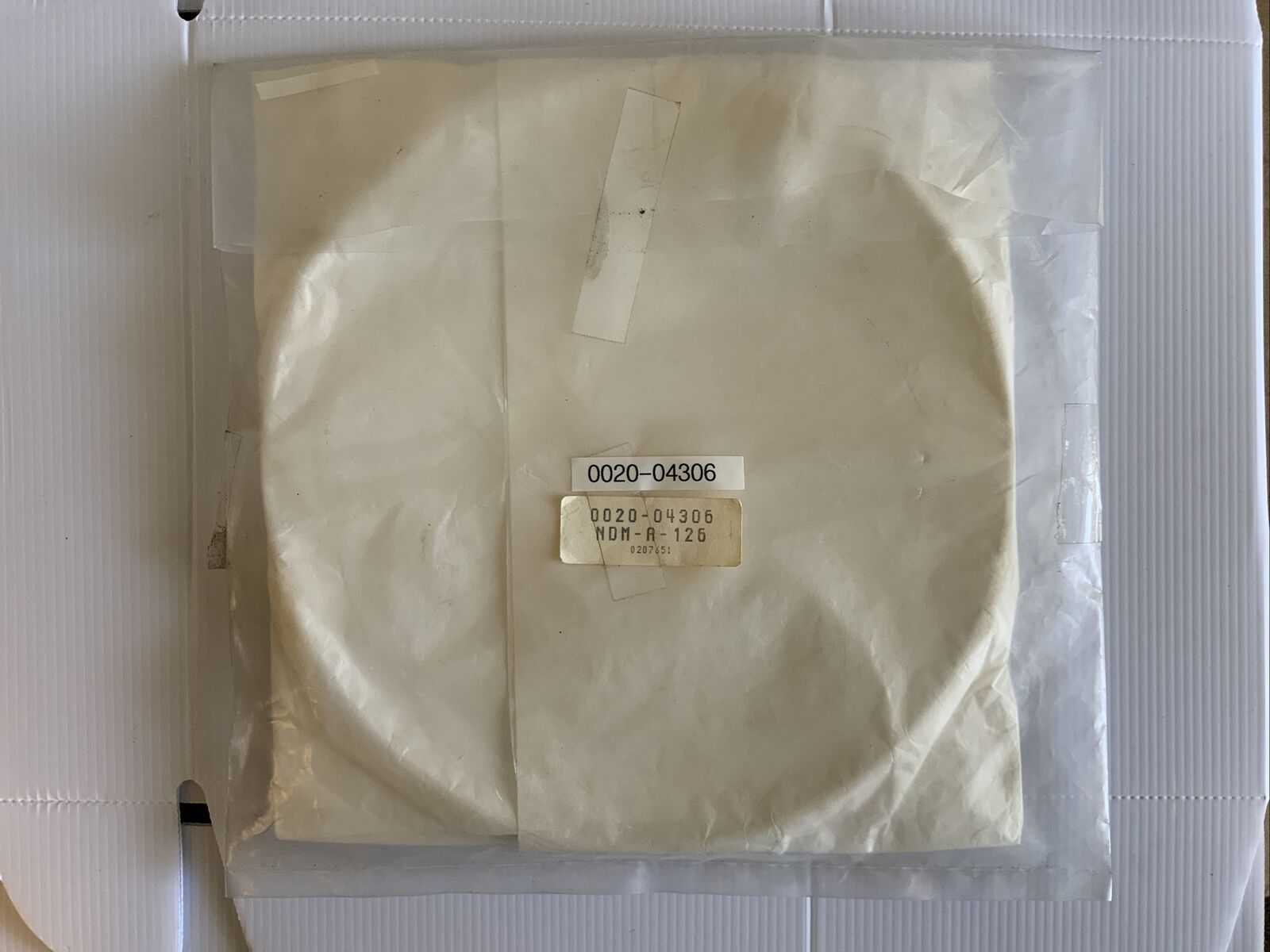

Electrodes:

Anode-coupled. Electrode spacing programmable and variable from 0.25 cm to 2.50 cm. 8" diameter, graphite "showerhead" type upper electrode.

Pressure Control:

Throttle valve pressure control system with adaptive controller. Capacitance manometer in process chamber. Thermocouple couples in loadlocks.

Range:

0.1 to 10.0 Torr

Temperature Control:

Remote DI water chiller (not included) for upper and lower electrode cooling. Continuous water quality monitoring with automatic shutdown.

Gas Delivery:

Five MFC's with Nupro-valve shut-offs and electrical actuators. Precharge system divers process gases from reactor during nonprocessing steps to maintain MFC stability and fast response.

RF Power:

Power SUpply:

Solid state 1250 W, 13.56 MHz, on board.

Impedance:

50 Ohms

RF Tuning System:

Automatically tunes to minimum reflected power, independent of gas species, pressure,and applied RF power.

Power Display:

Forward and reflected power displayed on CRT.

Machine Interfaces:

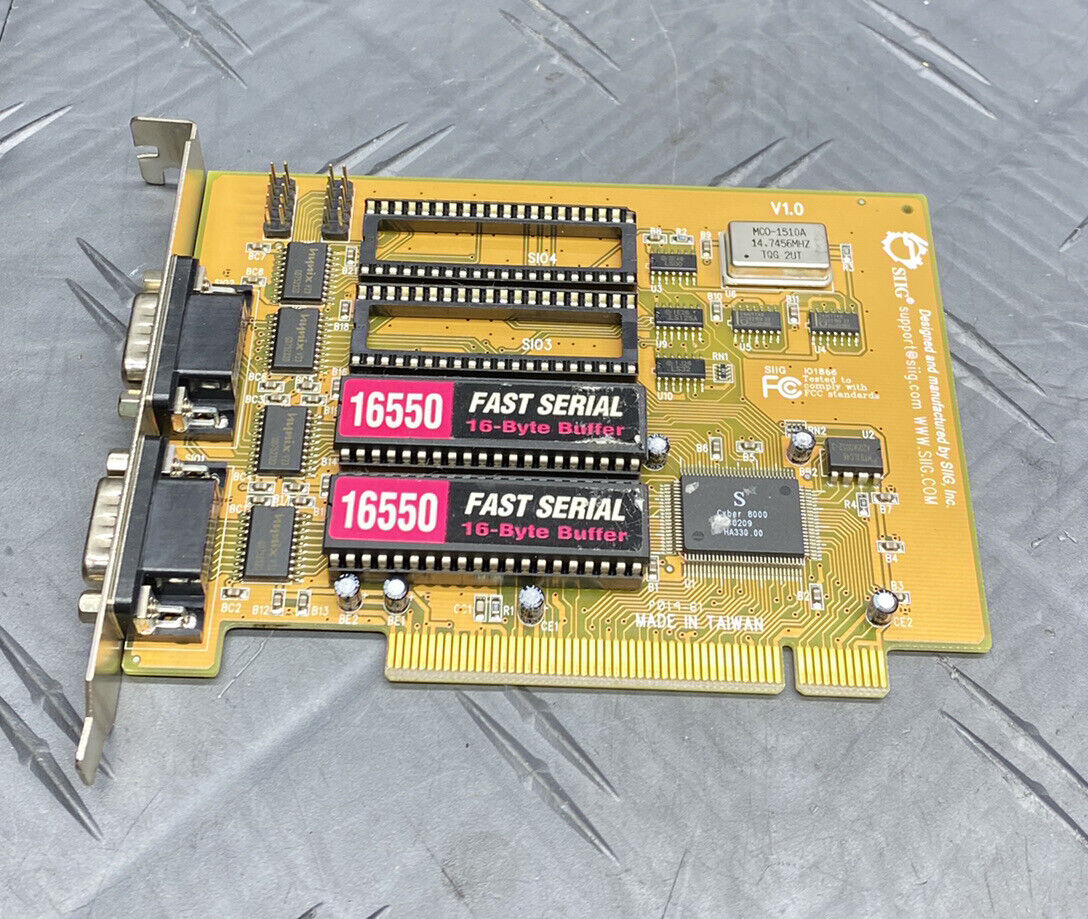

RS232C interface with optional (I don't know if this system has it) SECS II protocol. Bell 301-compatible, 300-baud modem.

Safety:

Vacuum loadlocks prevent exposure to toxis and odorous process gases. Hard-plumbed, scurbbed gas inlet line to maintain chamber. Sealed gas panel with scrubber failure interlock. Open chamber interlocks to MFC's and RF power. RF power supply interlocks. Purging operation for gas delivery system.

Diagnostics/Serviceability:

System monitors internal performance and reports alarms. Addressable and exercisable from remote locations through telephone modem. Lift-off front and side panels (panels are missing) provide full accessibility to internal assemblies.

Facility Requirements:

Electrical Power:

Etcher:

208 VAC, 3-phase, 50/60 Hz

Cooling Water:

3 gpm minimum at 10 psi differential pressure at less than 18°C (for RF power supply).

Compressed Air:

85 to 120 psi clean filtered dry shop air (-40°C dew point).

Dry Nitrogen:

Loadlocks:

10 psi, 8 CFM (intermittent)

Exhaust:

150 CFM for main frame cabinet. Additional exhaust required for load lock and process chamber mechanical pumps.

Connections:

Process Chamber Pump Line:

Type KF-50

Loadlock Pump Line:

Type KF-40

Process Gas Inputs:

1/4" VCR fittings

Dimensions:

44" W x 36" D x 55" H

Footprint:

44" x 36" (11 ft

2

)

Weight:

Approximately 950 lbs.

0.00 minimum for packaging, handling, and order processing. Shipping to be determined by destination.

Prior to shipment I will need to know the following information (filled out on a form that I will send you) for International Customers or Packages/Freight being Forwarded internationally. International customers may also be subject to a freight forwarder form if applicable.:

(1) Are you the end-user of this item?

(2) If you are not the ultimate end-user of the item, please state the ultimate end user's name.

(3) What is the ultimate country destination?

08/28/20